Exceptional

Switch Heating Systems

INDUCTION SWITCH HEATERS - FROG HEATERS - DERAIL HEATERS

Hot Switch Heating Systems: Unrivaled Efficiency and Performance

Hot Switch Heating Systems’ induction rail heaters are engineered for swift installation with minimal disruption and no track modifications, expandability, and unparalleled performance. These units employ cutting-edge magnetic induction technology instead of traditional resistance or forced air heating methods, setting a new industry standard.

With nine adjustable power settings, Hot Switch Heating Systems offer the highest rail temperatures in the market. You have the flexibility to manually adjust power levels or remotely fine-tune them to align with your existing infrastructure. Unlike conventional hot air blowers, our induction heads maintain consistent rail temperatures throughout the entire heated switch area and can be adjusted to concentrate more heat in specific problem areas within the switch.

Proven in the harshest of environments, from the frigid terrain of Alaska to the unforgiving lake effect snows of Ohio, Hot Switch Heating Systems have demonstrated exceptional reliability. In a head-to-head comparison, our equipment outperformed both hot air blowers and cal-rod systems during a 48-day period encompassing multiple winter weather events. The result: superior effectiveness and remarkable energy efficiency.

Moreover, investing in Hot Switch Heating Systems may make your organization eligible for The United States Green Energy Tax Credits, thanks to their remarkable energy savings, exceeding 60%. Elevate your rail heating system to new heights of efficiency and sustainability with Hot Switch Heating Systems.

- Optimized Energy Use: Enhanced efficiency through focused heat retention.

- Enhanced Safety: Reduced risk of malfunctions and accidents.

- Long-Lasting Solution: Durability minimizes replacements and repairs

- Quick Response to Weather Changes: Minimizes disruptions during adverse weather.

- Uniform Heating: Prevents uneven expansion or contraction issues.

- Reduced Maintenance Demands: Lowers wear and tear, and costs.

- Environmental Benefits: Reduced carbon footprint, potential for incentives.

- Improved Functionality in Extreme Conditions: Reliable operation year-round.

- Potential for Remote Monitoring and Control: Enhance operational efficiency through automation.

- Cost-Effective in the Long Run:

Significant long-term savings due to efficiency and durability.

A Better Way to Heat the Rail

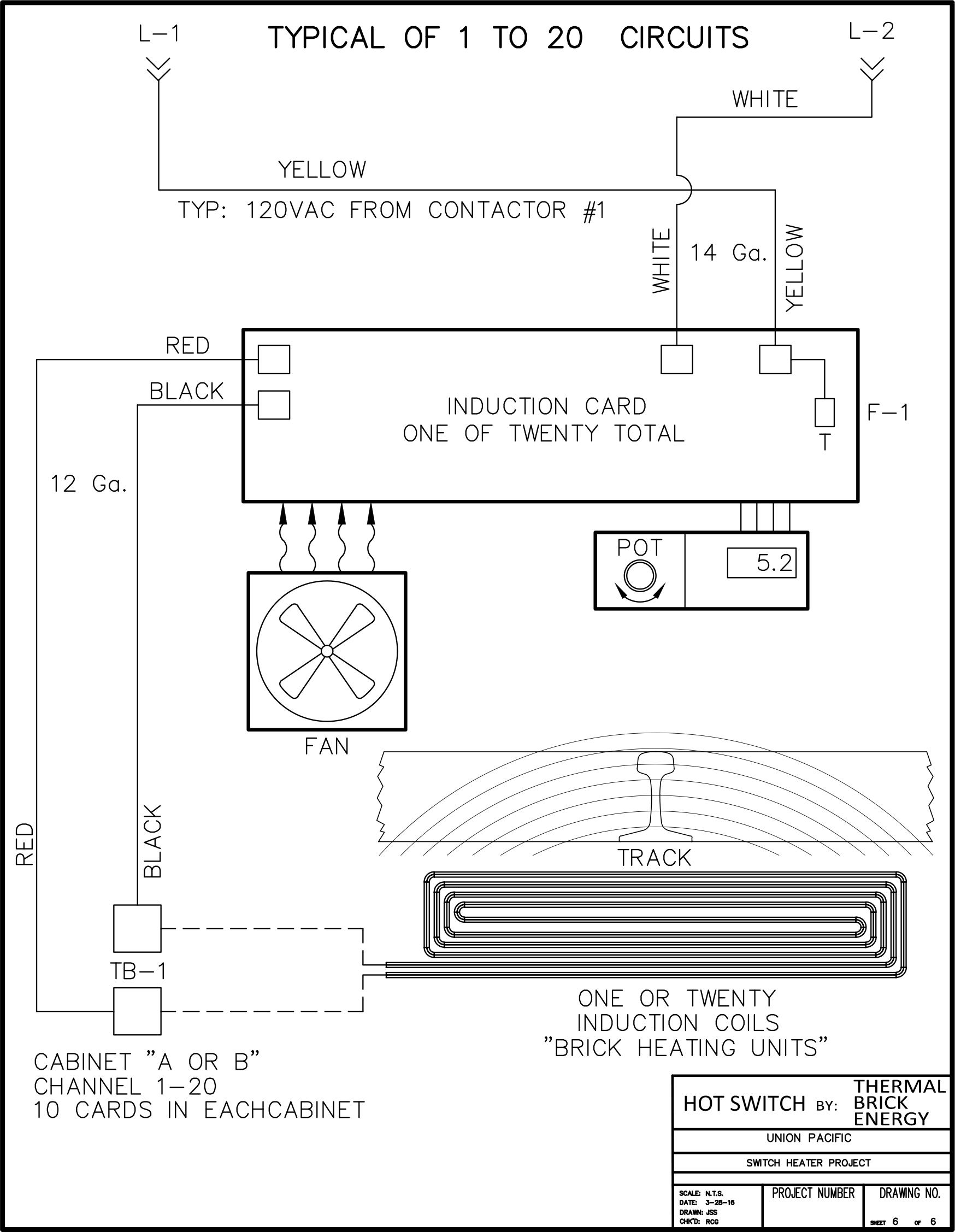

Hot Switch Driver Cards are located in the control cabinet. Smart Cards control all safety features and will auto-track weather events. Nine power settings are available either locally manual, local auto, or remotely as selected. Each Induction Head is powered by its own driver card and provides unmatched dependability so that even if there is a component failure heat is still being provided to the switch from the remaining driver cards and induction heads.

Performance:

Typical Railroad Switch

A typical switch setup would have up to eight induction heads on each rail and one or two Cribs depending on the size of the switch.

A typical #10 switch would be outfitted with five induction heads per side and one Crib unit. This system would use less than 40 amps of 120VAC to operate in the pulsed energy-saving mode.

Instantaneous Rail Heating: "30 seconds after powerup."

The rail temperature will be at or about 240 degrees F (set at 800 wats per head) depending on the weather conditions. A unit set up in this manner will use less than $ 60.00 dollars per month. "continuous operation"