TECHNOLOGY

the most powerful switch heater system on the market

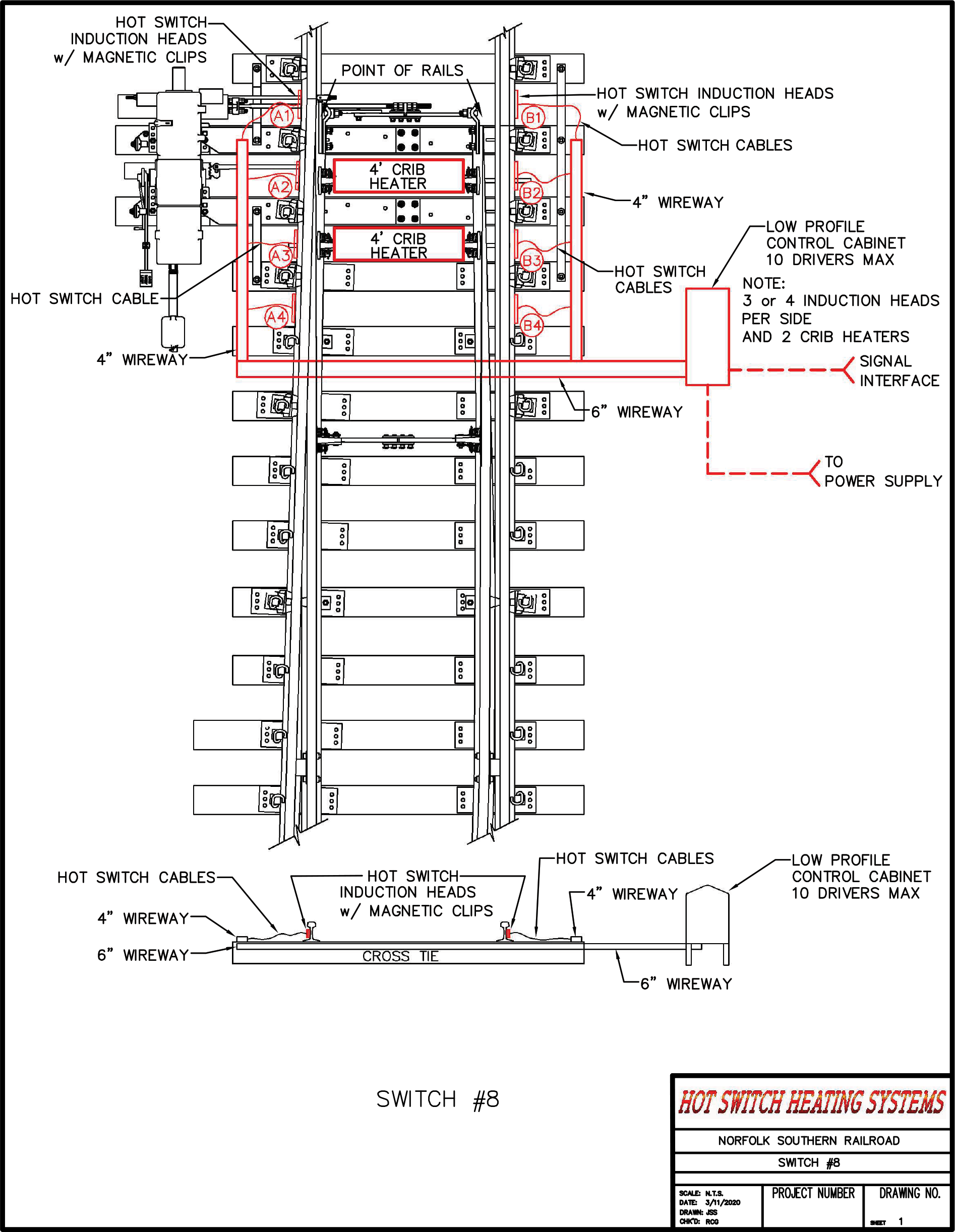

HOT SWITCH HEATING SYSTEM

How Does It Work

Experience the Future of Rail Heating: Induction Heating Simplified

Our patented switch heater system revolutionizes rail heating through the marvel of electromagnetic induction. Here's how it works:

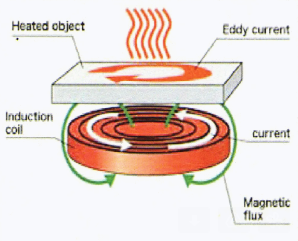

Electromagnetic Induction :

Within our system, a high-frequency alternating current courses through the induction coil within the induction head. This coil acts as an electromagnet, conjuring a powerful magnetic field that seamlessly penetrates the rail.

Eddy Currents :

As this magnetic field envelops the rail, it sets in motion a fascinating phenomenon known as eddy currents. These are oscillating currents that flow within the rail.

Molecular-Level Heat Generation :

Now, here's where the magic happens. The movement of these eddy currents inside the rail encounters resistance at the molecular level. This resistance, caused by the current, translates into heat production within the rail itself.

In simpler terms, our induction heating system efficiently and precisely warms the rail by harnessing the power of electromagnetic fields and eddy currents. This innovative approach not only ensures rapid and consistent heating but also minimizes energy waste, making it a smarter and more sustainable choice for rail heating needs.

Benefits of hot switch

Induction head drier Cards utilize a saw tooth wave form. With each driver card interparty operatory all heads will never simultaneously at peak power.

The magnetic field extends beyond the Hot Switch Induction Head on the side and covers up to 80% of the mass of the rail. As the surface area of the heat source is many times that of the Cal Rod, the heating efficiency is greatly enhanced over that of a Cal Rod.

The Induction Heads operate on 120 VAC or 240 VAC which is the most widely available operating voltage in the US and only consumes about six amps per head.

The HOT SWITCH Induction Head can deliver 500 to 1000 WATTS per foot on demand.

The system can instantly adjust power levels at the heads and neutralize a cold weather event.

Unlike the Cal Rod system, maintaining firm contact with the rail is not necessary. The HOT SWITCH Induction Head can be up to 1/2 inch away from the rail and the eddy current field is fully effective.

Should a problem occur with a head, it can be repaired in seconds while the other adjacent heads continue to heat the rail.

- New "Patented" Technology -

Railroad Switch Heater offers superior performance in the field while saving you money on operating costs!

Why Induction Heating Sets Us Apart

When it comes to rail heating, our induction-based system offers a host of advantages that elevate it above the competition:

Internal Heat Generation :

With our induction heating process, heat is generated within the rail itself, not reliant on an external heat source through conduction or resistive heating. This means rapid heating with remarkable efficiency.

Automated Efficiency :

Once the rail reaches its optimal temperature, our heaters seamlessly transition into a power-saving mode. This intelligent automation ensures efficient energy usage and minimizes operational costs.

Contact-Free Operation :

Our induction system requires no external contact, making it ideal for situations where space is at a premium or when other objects are in close proximity. This contact-free operation enhances safety and minimizes the risk of accidents.

Enhanced Safety :

Unlike other heating alternatives that demand a 480V 3-phase power supply, our product operates on a safer and more accessible 120VAC. This not only ensures the safety of your field personnel but also simplifies installation and maintenance.

Our induction-based railroad switch heater is not just a heating solution; it's a smarter, safer, and more efficient way to keep your rail operations running smoothly. Experience the future of rail heating with us.

Rapid Heat

Automatic Power Savings mode

Can heat tight spaces

Safer to operate 120VAC

Improved Operating Ratios

In a world where rail operators continually seek ways to streamline operations and minimize costs, Hot Switch Heating Systems induction switch heaters emerge as a game-changer. Here's why they offer a win-win solution:

Cost Savings :

Our switch heaters are designed to automatically transition to a power-saving mode once the optimal temperature is achieved. This intelligent feature not only reduces energy consumption but also significantly lowers operational costs.

Environmental Stewardship :

As rail operators increasingly focus on reducing their environmental footprint, our heaters come to the forefront as a meaningful solution. By choosing Hot Switch Heating Systems, you're making a tangible commitment to energy conservation. The result? Measurable reductions in energy usage, which align perfectly with your company's environmental initiatives.

Invest in efficiency, cost-effectiveness, and environmental responsibility with Hot Switch Heating Systems. We're not just keeping your rail operations running smoothly; we're helping you build a greener, more sustainable future.

Lower Costs

+

Less Environmental Footprint

=

Better Operating Ratio